Food safety isn’t just about what happens in the kitchen—it starts with how your refrigeration systems are installed. From walk-in coolers to reach-in refrigerators and refrigerated prep tables, temperature-controlled storage is one of the most critical compliance factors for any foodservice operation. Whether you’re running a restaurant, commissary, grocery store, medical kitchen, or institutional cafeteria, your cold storage equipment must consistently maintain safe temperatures to prevent contamination and foodborne illness.

This is exactly why professional refrigeration installation is not a “nice-to-have.” It is a compliance-driven requirement that influences everything from inspection results to inventory loss prevention and long-term operating costs. A poorly installed unit can create temperature fluctuations, airflow issues, drainage failures, or electrical problems that put food safety and compliance at risk—even if the equipment itself is brand new.

Below, we’ll break down why professional installation matters, how it impacts food safety compliance, and what businesses should evaluate when installing commercial refrigeration systems.

The Role of Refrigeration in Food Safety Compliance

Food safety regulations and health departments place heavy emphasis on temperature control. Bacteria multiply rapidly in the “danger zone” temperature range, so the primary objective of refrigeration is to keep perishable ingredients out of that range consistently.

Commercial refrigeration protects foods such as:

-

Raw meats and poultry

-

Dairy products

-

Seafood

-

Prepared sauces and cooked foods

-

Produce and ready-to-eat items

The challenge is that refrigeration compliance is about more than “it feels cold.” Inspections focus on measurable temperature performance, equipment integrity, and whether storage supports safe handling practices. Installation errors can prevent units from holding setpoints—even if they appear functional at first.

How Professional Refrigeration Installation Prevents Temperature Violations

Health inspectors commonly cite businesses for improper food temperatures. Many owners assume this is a staff issue, but in many cases, the real culprit is equipment performance—often linked back to installation.

Incorrect leveling causes inconsistent cooling

Refrigeration equipment must be level to allow proper door closure, gasket contact, and internal airflow. A unit that isn’t leveled can leak cold air or create temperature zones where certain sections run warmer than others.

Poor ventilation affects compressor performance

Commercial refrigeration needs adequate clearance for ventilation. If equipment is installed too close to walls, heat-producing appliances, or enclosed spaces with insufficient airflow, the compressor works harder and struggles to maintain safe temperatures.

Bad airflow design in walk-ins creates warm zones

Walk-in coolers and freezers require deliberate airflow planning. Placement of evaporator units, shelving layout, and return airflow zones all impact temperature stability. Improper installation can result in “warm corners,” which may trigger compliance failures.

A licensed installer ensures everything is calibrated properly from day one—reducing temperature fluctuations that can lead to violations.

Why Installation Impacts Health Department Inspections

A common misunderstanding is that inspections only focus on food handling. In reality, equipment condition is a major part of health compliance.

Professional installation supports:

-

Proper sealing and insulation integrity

-

Safe electrical setup and circuit capacity

-

Functional drainage and condensate management

-

Door alignment and gasket sealing

-

Stable temperature logging and monitoring compatibility

If a unit is installed incorrectly, your business can experience repeat temperature issues that show up during inspections—and those repeated issues may increase scrutiny from regulators.

This is where professional refrigeration installation becomes a foundational compliance decision, not an optional upgrade.

Common Installation Mistakes That Create Compliance Risks

Even minor mistakes can create major long-term problems. Some of the most common issues include:

1) Incorrect electrical requirements

Commercial refrigeration often requires dedicated circuits, correct voltage, and proper amperage. Overloaded circuits can cause performance drops, shutdowns, or intermittent cooling—putting food safety at risk.

2) Poor door seal installation

Gaskets must seal tightly. Misaligned doors or warped frames allow cold air leakage and humidity intrusion, causing inconsistent temps and ice buildup.

3) Improper condensate drainage

Drain lines must be properly routed and fitted to prevent pooling water. Standing water increases bacterial risk, creates slip hazards, and causes corrosion or mold.

4) Bad placement in hot zones

Installing refrigeration units near fryers, ovens, dish machines, or direct sunlight drastically reduces performance and causes internal temperature instability.

Professional installers account for real operational conditions—heat load, peak usage, product volume, and local code requirements—to ensure installation supports compliance.

Equipment Performance Affects Food Quality and Inventory Loss

Compliance isn’t the only reason installation matters. Refrigeration that underperforms causes:

-

Faster spoilage

-

Increased waste

-

Unsafe thaw/refreeze cycles

-

Inconsistent food quality (texture, taste, shelf life)

-

Unexpected breakdowns during peak business hours

A professional installation creates reliability and minimizes product loss—especially in high-volume kitchens where units are opened constantly throughout the day.

Energy Efficiency and Long-Term Operating Costs

Improper installation can cause refrigeration systems to run continuously, raising utility bills dramatically. Leaking seals, restricted ventilation, and poorly configured thermostat settings all force the compressor to overwork.

Professional installation includes performance testing and verification steps such as:

-

Checking temperature recovery time

-

Confirming defrost cycle settings

-

Ensuring airflow clearance meets manufacturer specifications

-

Verifying energy performance against expected load

Over time, that directly impacts operating costs and equipment lifespan.

Compliance-Focused Installation for Walk-In Coolers and Freezers

Walk-in systems are among the most compliance-sensitive refrigeration installations because they hold high-value inventory at scale.

A compliant walk-in installation must account for:

Insulated panels and vapor barriers

Poorly sealed panel connections allow moisture intrusion, causing condensation and mold growth. It also weakens insulation efficiency and affects temp stability.

Flooring and thresholds

Improper floor design creates sanitation issues and may violate code requirements for cleanability and accessibility.

Emergency safety features

Many jurisdictions require interior safety release mechanisms, appropriate lighting, and in some cases alarms or monitoring.

This is another area where professional installation ensures not only functionality—but code alignment.

How Professional Installation Supports Documentation and Audit Readiness

More organizations are adopting formal food safety systems such as HACCP plans and internal compliance audits. Your equipment installation and performance can become part of your documentation.

Professional installers can help ensure:

-

Equipment is installed to manufacturer requirements (important for warranty and inspections)

-

Temperature monitoring systems integrate correctly

-

Specs and technical documentation are organized for regulatory review

This is a strategic advantage for any operation aiming to scale, franchise, or serve institutional clients.

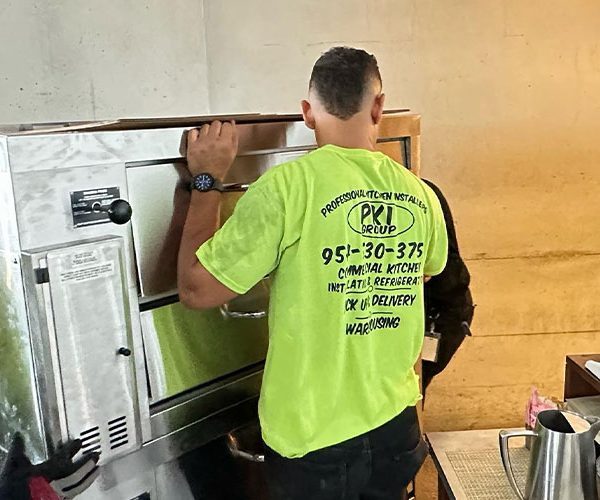

The PKI Group: Compliance Starts With the Install

Food safety compliance depends on consistency—and refrigeration is where consistency begins. Units that don’t maintain safe temperatures can trigger inspection failures, spoil inventory, and increase operational risk. The reality is simple: even the best commercial refrigeration equipment can fail compliance expectations if it isn’t installed correctly.

That’s why investing in professional refrigeration installation is one of the smartest decisions foodservice businesses can make. It protects customers, supports inspection readiness, prevents waste, and ensures your operation meets the standards required for long-term success.

If you’re planning a new install, kitchen buildout, upgrade, or replacement project, The PKI Group can help ensure your refrigeration installation is done correctly and compliantly—so your business stays safe, efficient, and inspection-ready.

Frequently Asked Questions

1) What temperature range is required for food safety compliance?

Most food safety standards require cold foods to be stored at or below 41°F (5°C). Freezers should remain at 0°F (-18°C) or lower to maintain safe frozen storage.

2) Can poor installation really cause temperature violations?

Yes. Improper airflow, bad seals, incorrect leveling, and electrical issues can all cause unstable temperatures—leading to food safety risk even if the unit is new.

3) How do I know if my refrigeration unit is installed correctly?

Signs of poor installation include temperature fluctuations, excessive frost, pooling water near the unit, doors that don’t seal properly, and compressors running constantly.

4) Is professional refrigeration installation necessary for warranty protection?

In many cases, yes. Manufacturers may require certified or professional installation to keep warranties valid, especially for large commercial systems.